-40%

HUGGER BELT SIDE GRIP TRANSFER CONVEYOR FOR BOTTOM CODING

$ 2216.01

- Description

- Size Guide

Description

WE DO SHIP TO THE ENTIRE US TERRITORY. PLEASE CONTACT US IF YOU HAVE ISSUES PLACING THE ORDER.IF YOU HAVE ANY QUESTIONS, PLEASE CONTACT US BY GOING TO THE

CONTACT SELLER OPTION ON THE EBAY PAGE.

We can adjust or make specific changes to this Conveyor to fit your specific needs and applications. Contact us, we are here to help you.

NEW STAINLESS STEEL BOTTOMLESS CONVEYOR SIDE BELT TRANSFER FOR BOTTOM CODING

BRAND: DEPENDABLE EQUIPMENTS

BEST QUALITY IN THE MARKET AT THE BEST PRICE

"DO NOT ACCEPT IMITATIONS, WE ARE THE ORIGINAL DESIGNER AND MANUFACTURER OF THIS CONVEYOR"

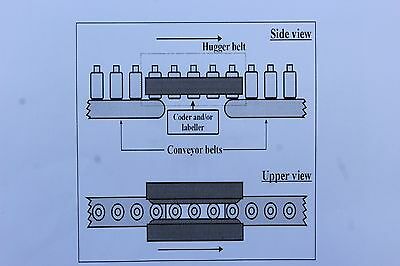

This Bottomless Conveyors are generally used for two primary functions:

1) As a bottomless conveyor integrated with an industrial inkjet coder for bottom coding of bottles or other products. Bottles are gripped on the side by belts that are driven at the same speed of the infeed conveyor and conveyed over an inkjet coder print head in order to apply lot codes, date codes, other text to the bottom surface of the container using a non-contact printing method (CIJ printer technology), ideal for labeling and verification inspection. The Gripper Belts are independently adjustable and can accommodate containers from 1 mm to over 7" in diameter.

2) As a bottle or product transfer conveyor. The transfer conveyor is placed in between two conveyors. Bottles or products are gripped on the side by the belts that are driven at the same speed as the infeed and exist conveyor in order to smoothly transfer the product from one conveyor to another. This eliminates dead plates which are normally placed at the exist or infeed of other machinery in order to transfer products. Dead plates can cause bottles or other products containers to tip over thus creating an obstruction and possible stoppage in the production line. The bottomless transfer conveyor allows for a smooth transfer thus eliminating bottle jam issues and ensuring more productivity.

STANDARD FUNCTIONS:

*Bottom Code various types and sizes of products

*Open design below belts for easy print head placement

*Safe design with no sprockets or chain underneath belts

*Ensures a smooth transfer of products from one conveyor to another

*No more products falling over due to metal transfer plates

*Easy and quick set up for various size and shaped of products with turn handle adjustments

CONVEYOR SPECIFICATIONS:

·

Stainless Steel and Duro Aluminum Construction

·

Variable speed control : 0 - 300 ft/min

·

Overall maximum machine dimensions: 37”L x 27”W x 34”H

·

Conveyor adjustable height : up to 40” (customization available)

·

Easy bottle size adjustment with hand wheel

·

Minimum bottle width : 1 mm Diameter

·

Maximum bottle width : 7” Diameter

·

Conveyor belt dimensions : 1”H x 36” L x ¾ “ Thickness

·

Motor Drive: 60 Watt, 3 phase, 50Hz, 1/12.5, 120 rpm

·

Electrical requirements : 115V / 1PH / 60HZ

****ADJUSTMENTS CAN BE MADE UPON REQUEST****

MOTOR SPECIFICATIONS:

BRAND - LONGWAY AC GEAR MOTOR

TECHNICAL SPECS

Enclosure: NEMA 4/12

Max. Amps: 3

Voltage Output: 0 to 90/180 VDC

Speed Range: 25:1

Rotation: Reversable

External Switches: CW/CCW

AC Input Voltage: 120/240 VAC

DC Speed Control: SCR

HP @ Lower Volts: 1/50 to 1/3

HP @ Higher Volts: 1/25 to 2/3

Linear Acceleration: Fixed 0.5 sec.

Current/Torque Limit: None

Speed Regulation: +/-1% of Base Speed

Shunt Wound Volts: 100/200 VDC

Accepts Tach Feedback: No

Dynamic Braking: No

IR Compensation: Adjustable

Follower Circuit: No

Mount Type: Compact Panel

Height: 5.5"

Depth: 3.5"

Width: 3.81"

Operating Temp: -10 Degrees to 45 Degrees C

Standards:

cULus Recognized

Includes: Speed Potentiometer Knob and Dial Plate

AC FREQUENCY DRIVE SPECIFICATIONS:

BRAND-TECO WESTINGHOUSE

Technical Specs

BRAND: TECO

MODEL #:

FM50-101-C

115 Volts, 1 Phase Input, 230 Volts 3 Phase Out.

HP :

1

Enclosure :

IP20

Input Voltage :

115

Input Phase :

1

Manufacturer :

TECO-Westinghouse

Output Voltage :

230

Output Phase :

3

Model :

FM50

A variable frequency drive is an electronic devise that allows you to start, stop, and control the speed of a three phase motor. It is also a motor starter as it is equipped with overload protection.

Variable frequency drives

now play an important part in major industry. Within the last 10 years they have been perfected to control and vary the speed of 3 phase electric motors. You may have heard them referred to as adjustable frequency drives, VFDs, and/or inverters.

Printer Head Bracket custom made to fit your printer FREE. Contact us for your Printer Head Dimensions.

WOOD CRATE DIMENSIONS AND WEIGHT:

48

" L x 25" W x 54" H

TOTAL WEIGHT: 180 Lbs

MADE IN THE USA

WE HAVE OUR OWN MANUFACTURING FACILITY

LOCATION: HIALEAH, FLORIDA 33013

"WE ARE SHIPPING THIS ITEM IN A WOOD CRATE" TO PROTECT IT.

FREE WOOD CRATE

ONE (1) YEAR WARRANTY ON PARTS

REFUND:

14 DAYS MONEY BACK. BUYER WILL BE RESPONSIBLE FOR RETURN SHIPPING COST. REFUND IS LIMITED TO THE ITEM PURCHASE PRICE EXCLUDING SHIPPING AND PACKAGING CHARGES. REFUND WILL BE ISSUED AFTER WE HAVE RECEIVED THE ITEM IN THE SAME CONDITION IT WAS SHIPPED TO YOU.

Freight shipments

must be thoroughly inspected

prior to accepting delivery. We are not responsible for any damages or shortages once a freight shipment has been signed for.

Any damages or missing items must be noted to the freight driver at the time of delivery.

CUSTOMIZATION AVAILABLE FOR THE ENTIRE US TERRITORY

PLEASE CONTACT US IF YOU HAVE ANY QUESTIONS, WE ARE HERE TO HELP YOU

THANK YOU

We process a large number of orders daily and unfortunately do occasionally make mistakes. However, leaving us negative or neutral feedback does not resolve the issue. We believe strongly in providing the best in customer service. If there is any problems with your order, please contact us by phone or via email through ebay. We will work with you to resolve any issue as soon as possible.